Magnetic test is an inspection method that uses magnetic fields and small magnetic particles (i.e. iron filings) to detect flaws in components. The component being inspected must be made of a ferromagnetic material.

In theory, magnetic test (MT) is a relatively simple concept, it can be considered as a combination of two nondestructive testing methods: magnetic flux leakage testing and visual testing.

The method is used to inspect a variety of product forms including castings, forgings, and weldments.

As applied from the given name, this type of test is involving the usage of magnet, either it’s permanent magnet or temporary magnet.

All magnets, no matter what their shape, have two regions called magnetic poles, which is North pole and South pole, with the magnetism both in and around a magnetic circuit producing a definite chain of organised and balanced pattern of invisible lines of flux around it. These lines of flux are collectively referred to as the “magnetic field” of the magnet.

North Pole is a pole where a magnetic line of force exits the magnet, and South pole is where a line of force enters the magnet.

When a magnet is broken in the center of its length, it will resulting on two complete magnets with magnetic poles on each end.

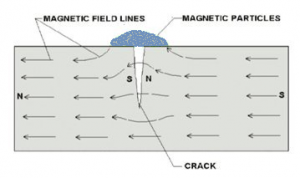

If the magnet is just cracked but not broken completely in two, a north and south pole will form at each edge of the crack.The magnetic field exits the north pole and reenters at the south pole.

The magnetic field spreads out when it encounters the small air gap created by the crack because the air cannot support as much magnetic field per unit volume as the magnet.

When the field spreads out, it appears to leak out of the material and, thus is called a flux leakage field.

If iron particles are sprinkled on a cracked magnet, the particles will be attracted to, and cluster not only at the poles at the ends of the magnet, but also at the poles at the edges of the crack.

This cluster of particles is much easier to see than the actual crack, and this is the basis for magnetic particle inspection.

The first step in a magnetic particle inspection is to magnetize the component that is to be inspected.

If any defects on or near the surface are present, the defects will create a leakage field.

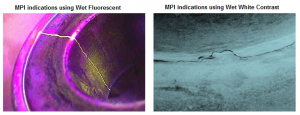

After the component has been magnetized, iron particles, either in a dry or wet suspended form, are applied to the surface of the magnetized part.

The particles will be attracted and cluster at the flux leakage fields, thus forming a visible indication that the inspector can detect.

Advantages & limitations

Some of the advantages of Ultrasonic inspection include:

- Sensitive to both surface & near-surface discontinuities.

- It gives immediate indication of defects.

- It is quick and relatively uncomplicated.

Some of the limitations of Ultrasonic inspection include:

- Restricted to ferromagnetic material.

- Can’t be used in thick painted materials.

- Materials that are rough, irregular in shape, very small, exceptionally thin or not homogeneous can cause spurious indications.

The Magnetic course combined with Penetrant course will consist of 6 days for Training (theory & Practicum) + 2 days for exams. The course outline and syllabus is . . .